Innovative Printing Techniques

New can printing techniques help brands make their mark.

With production reaching an incredible 61 billion cans/year, the sheer size of the European beverage can industry suggests that it might be hard to make your product stand out on the shelf. Cans stand out compared to other packaging formats, and a specially printed can even gets more attention.

New and innovative print techniques have revolutionised the possibilities available to beverage companies and enable each one of them to promote their brands in an original way.

This means that marketers now have many new and exciting ways to deliver better value for money, higher engagement and a product-containing advertisement to the consumer.

A delight for the senses

One of the most effective and original options available to brands is the ability to create a can with a special and unique finish. These new branding techniques include, amongst others, photochromic and thermochromic, matte OV and neon inks & finishes: the possibilities are wide and varied.

Technique 1: Thermochromic and photochromic beverage can printing ink

Thermochromic and photochromic inks make beverage cans chameleon-like in their colour-changing capabilities. The final visual impact might be similar with these 2 techniques, the way to the result is totally different:

- Thermochromic inks cover a part of the can with a temperature-sensitive pigment that could, for example, let consumers know when the beverage has reached the optimal temperature for consumption.

- Photochromic inks change colour when exposed to bright sunlight, potentially revealing new images, colours and messaging. The latest developments on photochromic inks mean cans are able to change colour almost instantly when exposed to sunlight giving a kind of “on/off” effect.

(image above) Example of photochromic ink that changes colour when exposed to bright light.

Technique 2: Glow in the Dark and Neon beverage cans printing

Glow in the Dark and Neon inks are perfect for brands looking to add more impact to their products, especially at night.

- The Glow in the Dark ink appears white in daylight whilst it is absorbing light, and then gives off a gentle hue of green when in darkness.

- Neon inks are the solution for venues such as nightclubs and bars. Parts of these cans shine intensely under UV light. Ideal for highlighting the brand name or other eyecatchers of the can design.

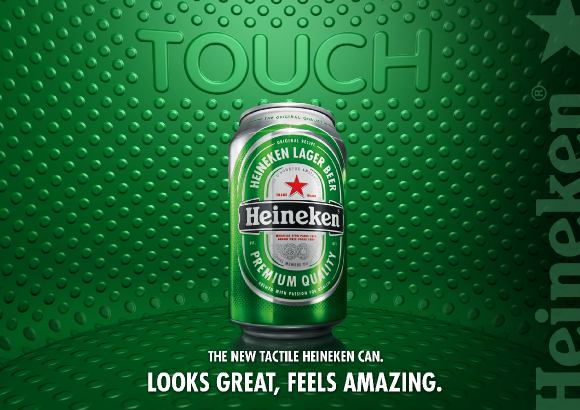

Technique 3: Tactile OV - Experiencing the product

Tactile OV uses a special coating technology that gives consumers a tactile experience with the product. Different surfaces can be felt while holding the can, making it particularly effective in picking out certain elements of an image.

(image above) This Heineken can gives a pleasant tactile experience and the impression of condensation a the can when you drink ice cold beer

Technique 4: High Definition Beverage Can Printing

High Definition ink offers more creative design options and allows for that very detailed images to be reproduced on cans. Instead of simplifying a print or online advertisement for a can derivative, the same detailed image can be used in all executions of the creative process.

from other packaging formats. After all, in a crowded fridge or supermarket shelf, every extra effort counts in making one product stand out from the other and attracting the attention of the consumer.

While these interactive technology inks are more costly than traditional printing, they do give brand owners the ability to add originality and more fun into their customers’ beverage experience.

24 times the same, but different

For a brand working on a large campaign, it’s particularly interesting if they can produce more than just one design. Not only does the overall effect look bold and strong on the shelves, a number of variations of the product will also often entice consumers to seek out and collect the multiple different versions.

Technique 5: Variable beverage can printing

Thanks to variable printing techniques, a multitude of designs can now be printed on a single pallet. Up to 24 different designs can be integrated into existing print processes for all sizes of cans. This allows customers to develop and deliver special promotions with ease.

Brands are no longer limited to having only one or two visual designs … instead they can offer a much more personal and targeted approach.

And the retailers? They appreciate the excitement of the novelty and the on-shelf appeal, as well as the returning customers!

Baltika #3, one of Russia’s most popular beer brands, created 990 different can designs for a first of its kind limited collection. The stand out 50cl cans displayed the names of 990 different Russian cities printed with an identical urban skyline graphic. Malkiel Natalia, Brand Manager Baltika #3, confirmed, “We wanted to encourage national pride and unify our loyal Russian consumers across the country through the product itself. It was a tall order but we knew the latest printing and manufacturing technology were available to deliver!”

Sports sponsorship and branded cans show the way

Did you know that the sports sponsorship market worldwide is estimated to be worth more than US$45 billion per year?

There is a growing trend for brands to design their packaging around the team or event they are sponsoring.

After all, sponsorship on packaging is a medium that consumers can’t ignore according to Steve Osborne, Managing Director of packaging and branding design agency Osborne Pike.

He says, “packaging is media, but it’s unlike any other medium because it also contains the product. This gives it a unique position because it acts at the very moment of purchase and also at the moment of consumption”.

Examples:

- Carlsberg, the official beer of Euro 2016, created football-themed limited-edition packaging. They used their normal brand colour of green but also added the tournament colours of red, white and blue. Their export limited edition beer can had a gold and silver design with French landmarks taking the place of the studs on the bottom of a football boot.

- Coca-Cola also launched limited-edition packaging to mark its sponsorship of Euro 2016, with cans featuring relevant star players for each European market and an additional series with the team colours of each competing nation. And as sponsor of the 2016 Olympics, Coke worked with a local Brazilian artist to make a series of limited-edition can designs.

Budweiser: the technology is also beginning to have an influence on the cans’ design possibilities. For their sponsorship of the FA Cup, Budweiser used an augmented reality (AR) app that enabled consumers to turn their 440ml can into a 3D model of the FA Cup.

Technique 6: Beverage Cans - Lasers can personalise each can

Laser coders are another highly effective way of printing all kinds of information on beverage packaging. For example, logos, barcodes, serial and lot numbers, or unique codes for competitions and sweepstakes can be added to the can.

Laser coders work either by ablation, etching or foaming. In ablation, the laser removes the outside layer of ink on a printed product that then shows the background color underneath. The heat of the laser beam in the etching process melts the surface and leaves a raised mark. Finally etching is a good choice for high-speed marking because the substrate material is almost instantly etched with each laser pulse.

(image above) The QR-code is situated under the tab, meaning the can only be scanned once it has been opened

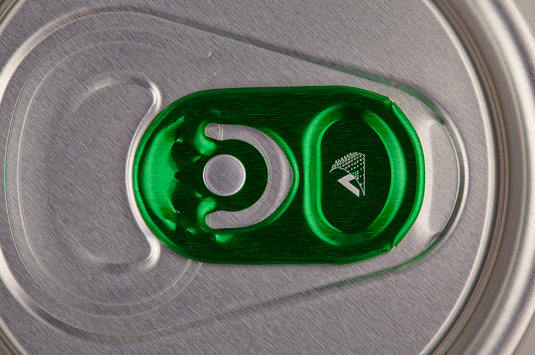

Technique 7: The beverage can tab is optimal media territory

Also drink tabs provide a surface area for branded messaging and promotions. It’s possible to laser-etch exceptionally fine text and logos onto filled-in tabs. These laser-etched tabs (LETs) can of course be combined with the other printing techniques for added impact and engagement.

(image above) Laser etched tabs provide new surface area for branded messaging and promotions.

Yes, you can

There are huge opportunities for the beverage industry with cans. An enormous number of options are available when it comes to innovative printing techniques, giving cans a competitive edge that makes them stand out from the crowd.

So while a simple can design may seem like a small element of the marketing puzzle in a large campaign, it’s a good idea to give it your full attention.

What sort of innovative design and printing techniques are you considering for your brand? Do you have new innovative ideas? Talk to us on info@metalpackagingeurope.org, LinkedIn, Facebook or Twitter

--

Metal Packaging Europe gives Europe’s rigid metal packaging industry a unified voice, by bringing together manufacturers, suppliers, and national associations. We proactively position and support the positive attributes and image of metal packaging through joint marketing, environmental and technical initiatives.

Stay up to date with more insights and subscribe to our mailing list >>